Energy

We support access to affordable and reliable energy, optimize energy consumption and seek to minimize energy intensities. SDG #7, Affordable and Clean Energy

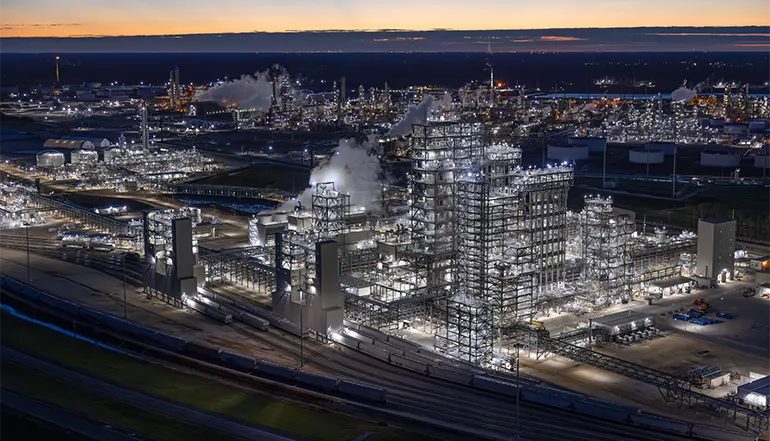

Our company purchases energy in the form of fuel, electricity and steam. Additionally, our manufacturing facilities utilize by-product fuels generated during operations to produce energy on-site. Longstanding programs at CPChem focused on reliability and energy management enable reductions in carbon intensity and improvements in other air emissions performance.

In 2024, CPChem’s equity global energy consumption reached 229 million MMBtu, with an energy intensity of 5,703 Btu per pound of product on an operated basis. Total energy consumption increased in 2024, partly due to higher fuel consumption and production figures. CPChem’s manufacturing teams continuously strive to enhance efficiency across our facilities and improve energy performance.

Energy Consumption*

Energy Best Practice Teams

CPChem empowers site Energy Best Practice Teams to enhance energy performance and spearhead energy reduction initiatives. Team leaders regularly convene to exchange best practices, celebrate achievements, and challenge one another to creatively meet the company’s energy goals.

One tool our teams use is a facility-level energy intensity index. This calculation allows facilities to standardize benchmarking and monitoring efforts while tracking annual progress toward energy reduction goals. CPChem’s energy intensity index for 2024 in various regions was 0.72 (Europe), 0.90 (Singapore) and 1.04 (United States). See our 2024 Performance Data Tables for more details on energy performance.

Energy Reduction Site Awards

In 2024, CPChem received two awards from the American Chemistry Council for outstanding energy performance at our Old Ocean, TX facility, where polyethylene assets reduced energy consumption per pound of product. Energy reductions were achieved through steam and fuel consumption optimization in equipment and operations. This project was completed through our MACC process, and after a full year of operation, has resulted in a greater than 40% reduction in fuel consumption of assets at this location.

Regional Energy Index and Energy Intensity

** Energy intensity is reported on an operated basis and represents 100% stake for wholly owned operations, with the exception of Performance Pipe.